Devices that almost everyone has such as eyeglasses or cameras include lenses – optical components with spherical or cylindrical surfaces, or slight deviations from such shapes. However, more advanced optical functionalities can be obtained from surfaces with complex surface features.

At present, making such freeform optics is very difficult and expensive because of the specialized equipment needed to mechanically process and polish their surfaces. But Israeli researchers have developed a way to create freeform optical components by shaping a volume of curable liquid polymer (that can be hardened). The new method will make possible the faster prototyping of customized optical components for a variety of applications including corrective lenses, augmented and virtual reality, autonomous vehicles, medical imaging and astronomy.

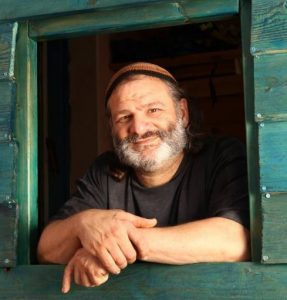

“Our approach to making freeform optics achieves extremely smooth surfaces and can be implemented using basic equipment that can be found in most labs,” said research team leader Moran Bercovici at the Technion-Israel Institute of Technology in Haifa. “This makes the technology very accessible, even in low resource settings.”

In Optica, Optica Publishing Group’s journal for high-impact research, Bercovici and colleagues showed that their new technique can be used to fabricate freeform components with sub-nanometer surface roughness in just minutes. Unlike other prototyping methods such as 3D printing, the fabrication time remains short even if the volume of the manufactured component increases.

“Currently, optical engineers pay tens of thousands of dollars for specially designed freeform components and wait months for them to arrive,” said Omer Luria, one of the contributors to the paper. “Our technology is poised to radically reduce both the waiting time and the cost of complex optical prototypes, which could greatly speed up the development of new optical designs.”

The researchers decided to develop the new method after learning that 2.5 billion people around the world don’t have access to corrective eyeglasses. “We set out to find a simple method for fabricating high quality optical components that does not rely on mechanical processing or complex and expensive infrastructure,” said Valeri Frumkin, who first developed the method in Bercovici’s lab. “We then discovered that we could expand our method to produce much more complex and interesting optical topographies.”

One of the primary challenges in making optics by hardening or toughening a liquid polymer is that for optics larger than about two millimeters, gravity dominates over surface forces, which causes the liquid to flatten into a puddle. To overcome this, the researchers developed a way to create lenses using liquid polymer that is submerged in another liquid. The buoyancy counteracts gravity, allowing surface tension to dominate.

With gravity out of the picture, the researchers could fabricate smooth optical surfaces by controlling the surface topography of the lens liquid. This entails injecting the lens liquid into a supportive frame so that the lens liquid wets the inside of the frame and then relaxes into a stable configuration. Once the required topography is achieved, the lens liquid can be solidified by UV exposure or other methods to complete the fabrication process.

After using the liquid fabrication method to make simple spherical lenses, the researchers expanded to optical components with various geometries — including toroid (form with a hole in the middle) and trefoil (like a three-leafed plant) shapes — and sizes up to 200 mm. They show that the resulting lenses exhibited surface qualities similar to the best polishing technologies available while being orders of magnitude quicker and simpler to make.

In the study published in Optica under the title “Fabrication of freeform optical components by fluidic shaping,” they further expanded the technique to create freeform surfaces by modifying the shape of the supportive frame.

“We identified an infinite range of possible optical topographies that can be fabricated using our approach,” said Mor Elgarisi, the paper’s lead author. “The method can be used to make components of any size, and because liquid surfaces are naturally smooth, no polishing is required. The approach is also compatible with any liquid that can be solidified and has the advantage of not producing any waste.”

The researchers are now working to automate the fabrication process so that various optical topographies can be made in a precise way that can be repeated. They are also experimenting with various optical polymers to find out which ones produce the best optical components.

The shortcode is missing a valid Donation Form ID attribute.